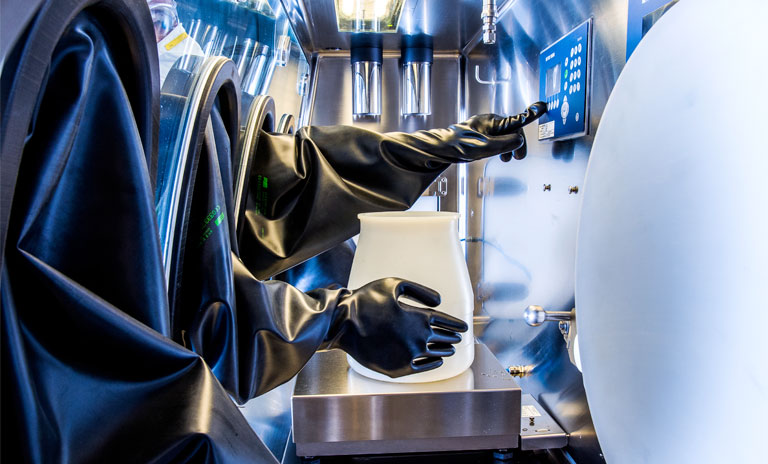

Dispensing and Sub-division

Extract Technology dispensing and sub-division isolators are suitable for both large and small scale operations. They provide operator, environment and product protection, and facilitate both the loading and unloading of products which require containment. They enable bulk and process container product transfer, feature integrated weighing systems, and afford low OEL protection. They are available in a range of versions, giving transfer from differing bulk containers into FIBCs, drums, process vessels, bags or liners.

Sampling Isolators

Extract Technology Sampling Isolators are ideal for use in warehouse or production areas. They provide low OEL protection and can be used in both positive and negative environments. A range of options are available, including contained sample removal and multi-chamber protection.

Charging and Formulation

Extract Technology Charging Isolators enable the manual charging of product by weight or volume. Auto product feed to weight systems with contained bulk container load/unloading is possible for use on either same floor process or multi floor charging systems. You can choose from a number of product transfer configurations from a range of vessels into IBC’s, FIBC’s, drums, reactors, vessels, sacks or bags, all with the option of safe empty drum “bag out” removal system.

Process Offloading Isolators

Extracts Technology Pack Off Isolators allows you to precisely offload to weight, whilst providing product, operator and environment protection. Creating a physical barrier between the operator and product these units are capable of handling some of the most potent pharmaceutical compounds. Two chamber pack off isolators incorporate automated in-feed and out-feed conveyors, product control, inserting system and product sampler. Product pack-off isolators accommodate multi drum sizes and continuous liner facilities.