THOUGH MADE TO ORDER...

Facilities are usually designed around our standard downflow booth sizes which can be suitably selected to accommodate the client’s process. Facilities can be designed to house any operations from small scale sampling to large material handling processes - operational aids such as post hoists, conveyor lines, workbenches etc. can be integrated into the equipment.

Design

Optional Design Study Facility

Extract Technology offer a full design study service which allows the client to fully investigate all possible containment solutions with a minimum outlay. A typical design study involves a detailed site survey and process discussion to establish the full extent of the project. Next the engineering designs, specifications and costing are generated before a full on site presentation is undertaken. An additional option involves the construction of full mock-ups for review by the client.

Custom

to suit the process

Turnkey

solutions available

Design Advantages

- Internal furnishings

- Battery backup LED lighting in airlocks

- PLC control with touch screen HMI interface available

- Signalling between facility and clients BMS available

- Rapid roller shutter doors for material entry and exit

- Single pass airflow for solvent/liquid handling available, complete with full air handling packages

- Cascading pressure regime

Available Options

- Mobile work benches

- Hazardous area electrics option

- Flush mounted computer integration

- Pallet stop rails

- Cooling coils and controls

- Increased internal height

- Incorporation of lifting and tipping equipment

- Materials and personnel airlocks systems

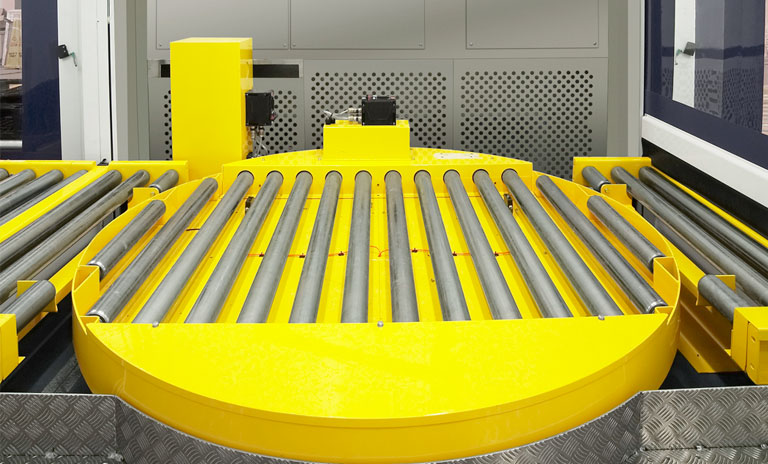

- Roller conveyors, rapid roller doors and turntables

- Customization available on request

Installation & Commissioning

Every installation is either fully undertaken by Extract Technology qualified engineers or supervision by our highly experienced engineers.

Commissioning & validation services are undertaken, along with comprehensive operator training packages. Full test reports and reports and IQ/OQ documentation can also be provided.

Designed to satisfy both current and projected industry standards it provides pharmaceutical and chemical companies with a clear guide to assessing the level of containment required to safely handle differing hazardous materials.

Customer Support

Our planned maintenance and re-certification package provides a scheduled visit to undertake a full range of testing to industry standards.

Service UK: +44 01484 354 499

Service Americas: +1 608-747-2482

Spare Parts Americas: +1 608-747-2475

Containment Strategy

The selection grid at the heart of the Control Strategy Pyramid permits the exposure potential rating and operator exposure band to intersect at the recommended Control Strategy selection. This is a simple cross reference to identify the correct equipment to be used to control and handle a specific process.