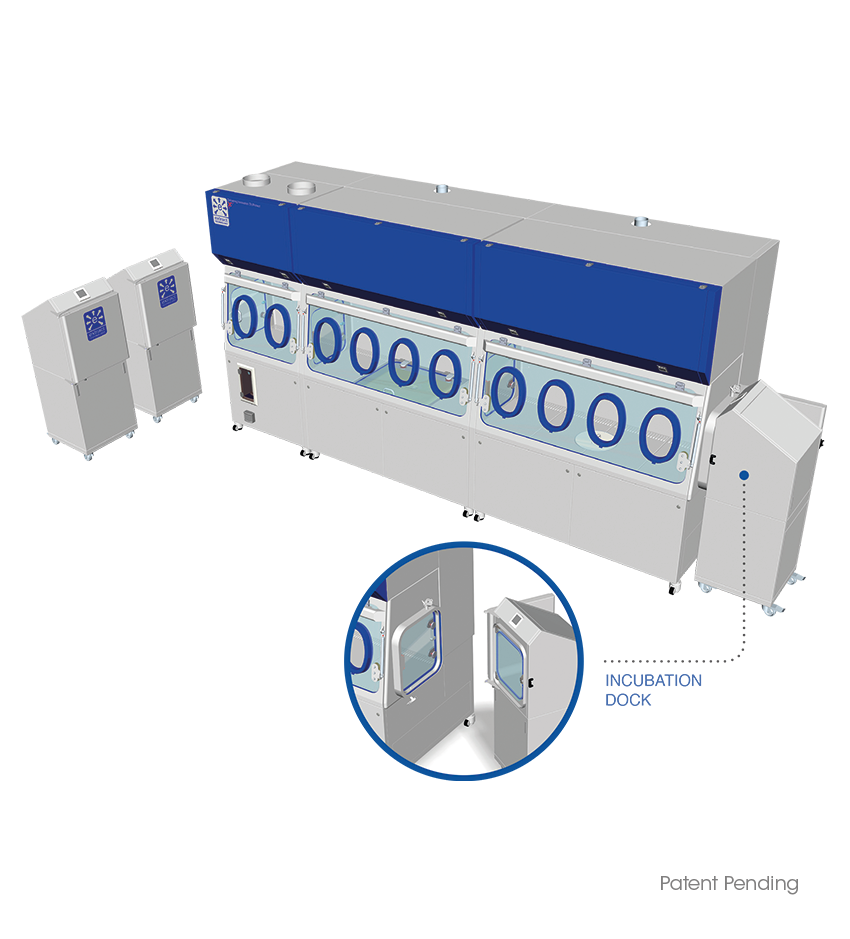

Modular Cell Therapy Isolator

As part of the standardised product range, the Modular Cell Therapy Isolator is a standard cost effective alternative solution for the safe processing of cells. Available in a basic configuration but with a wide range of optional integrated equipment it can be increased in both size and flexibility to satisfy specific process requirements. A Grade A/ISO 5 temperature controlled and bio-decontaminated chambers make processing cells safe for patients.

Description

A modular system enabling an increase working area with dockable incubators allowing multiple cell cultures to be treated separately.

The on board rapid gassing system enables the operators to handle cellular products in a highly controlled process flow. The bio-decontamination ensures a 6 log reduction in bacterial spore population with inclusive safety features to guarantee operator and plant safety. Increased protection from contamination is achieved by reducing human interventions, physical barrier technology, pressure differential and routine Hydrogen Peroxide Vapour Decontamination.

Bio-decontamination

Reduction in spore population

Gassing time

Based on empty chamber

Air Classification

Unidirectional airflow

Design Advantages

- Ergonomic design generated by the use of sloping front face, large oval PharmaPort gloveports

- cGMP compliant design

- Increased safety by reducing contamination risks (ensuring product compliance)

- Full process equipment integration with Grade A ISO 5 Environment

- Isomon full H2O2 high/low level monitoring integrated into the control system

- External H2O2 sensor for room monitoring

- Safe change filters

- Different pressure cascade within each chamber

- Energy efficient

- Integrated Vapour Phase Hydrogen Peroxide Decontamination

- Dockable incubators with Patent Pending Aseptic Docking System (ADS)

- Space saving design

- PLC Controlled System with HMI interface

Available Options

- Chart recorder and associated integration cost

- Viable Particle Monitoring

- Non-viable particle monitoring

Chamber Configuration Options

- Grade A ISO 5 process chamber with integrated fridge

- Transfer hatch

- Centrifuge chamber

- LAF cabinet for cell introduction

- Dockable incubator pod

Customer Support

Our planned maintenance and re-certification package provides a scheduled visit to undertake a full range of testing to industry standards.

Service UK: +44 01484 354 499

Service Americas: +1 608-747-2482

Spare Parts Americas: +1 608-747-2475