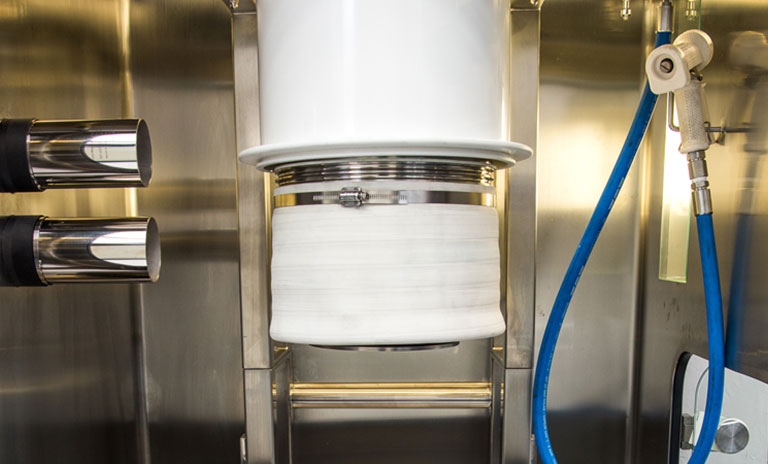

Continuous Liner Discharge

On disconnection of any make and break connection “sealing head inflate/deflate” the issue of powder discharge from the upstream process chute into the atmosphere becomes a contamination issue not only for the operator and surrounding environment but also for the product. By forming a continuous flexible barrier between the process and the surrounding environment this can be prevented.

Horizontal Laminar flow booths

A “once through” even laminar airflow is pulled uniformly across the work area to the rear plenum, extracting any airborne particulate away from the operator and into the fan/filter unit or to the clients own dust collection or scrubbing system.

All units are designed specifically for the application, and are supplied with a fan and motor system, suitably zoned for the application area.

A fully welded stainless steel construction; they can also incorporate weighing and control systems as required.

Containment levels achievable of between 1-20µg/m3.

X-Flow Booths

A unique design of crossflow or “side to side” airflow removes any airborne particulate away from the operators breathing zone. Air is introduced from one of the side plenums at a constant velocity and is then exhausted at the opposite side, passing through fine dust and Hepa filters before being recirculated back into the booth.

Pack Off Isolators (For Process Offloading)

Single chamber fully welded 316L stainless steel construction.